Comparing efficiency: Lead-acid vs lithium-ion batteries for industrial electric vehicles

Electric industrial vehicles rely solely on electricity for operation. They utilize one or more electric motors powered by rechargeable battery packs.

The efficiency of battery packs varies depending on the technology and operating conditions. Efficiency is determined by the ratio of useful power output to total electrical power consumed, with any gap primarily attributed to heat losses.

Lead-acid batteries

Balancing efficiency and operational needs

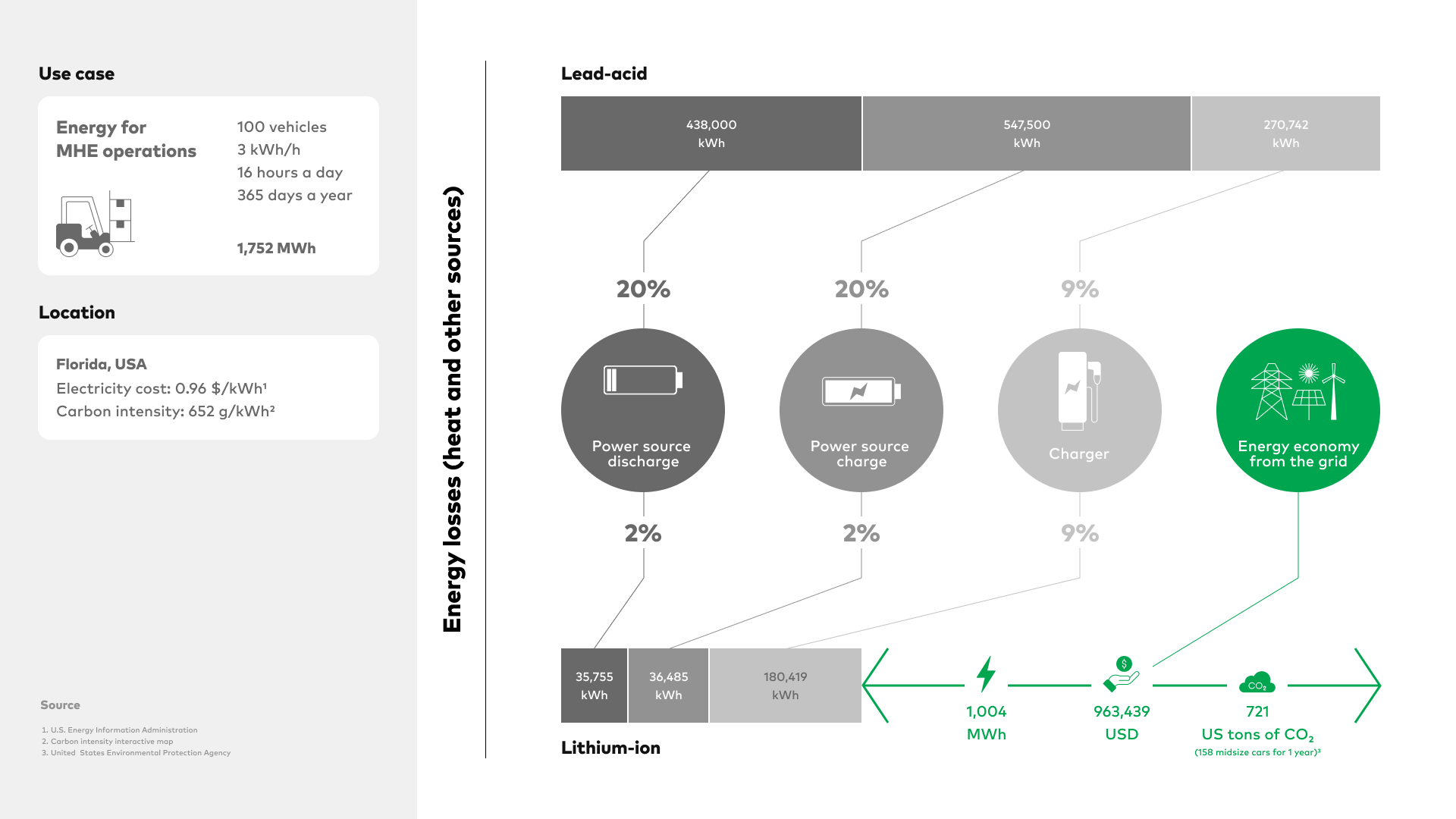

Lead-acid batteries boast approximately 80% efficiency when it comes to converting stored charge. The roundtrip efficiency from grid to truck is therefore in the range of 57%. Optimal efficiency can be achieved through slower charging and discharging rates, but the demands of material handling operations often require faster charging times.

Lithium-ion batteries

Maximizing efficiency and minimizing losses

Lithium-ion batteries exhibit an impressive charging efficiency of 98%, effectively minimizing losses associated with heat dissipation. The roundtrip efficiency of lithium-ion batteries is therefore closer to 87%.

Enhancing material handling operation efficiency

During the operation of an industrial vehicle, energy from the grid is transmitted through chargers, stored in the power source, and subsequently released to facilitate various movements such as travel and lifting. The less friction there is in the movement of the electrons, the lower the losses and the higher the efficiency.

Scenario analysis: Energy efficiency and cost evaluation

Let’s take, for example, a warehouse with 100 vehicles, each requiring 3 kWh/h of energy, operating for 16 hours a day, 7 days a week. The transition from lead-acid to lithium-ion batteries results in an energy efficiency gain of 1,003 MWh.

In Florida, where electricity is predominantly generated from natural gas and costs 0.096 $/kWh according to the U.S. Energy Information Administration (EIA), and where the carbon intensity is 652 g/kWh, as observed on Electricity Maps, adopting lithium-ion batteries represents an annual cost saving of US$96,344. Additionally, it leads to a reduction of 721 US tons of carbon emissions annually.

See an interactive map of the impact of electricity on Electricity Map.